1. Kev Ntsuas Kev Ntsuas thiab Kev Ntsuas

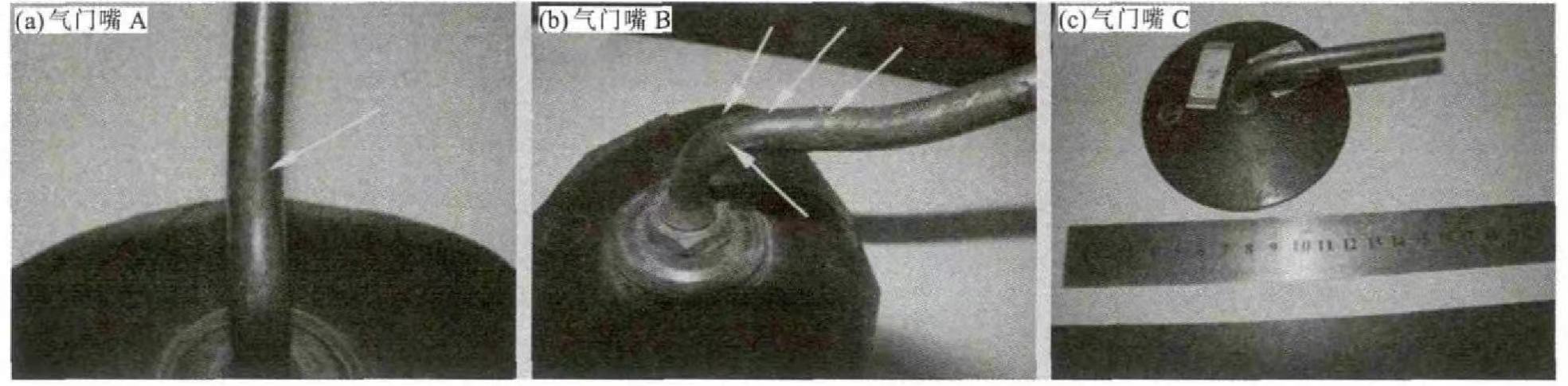

Ntawm 3log tsheb li qubcov qauv muab los ntawm lub tuam txhab, 2 yog li qub, thiab 1 yog lub valve uas tseem tsis tau siv. Rau A thiab B, lub valve uas tsis tau siv yog cim grey. Daim duab 1. Sab nrauv ntawm lub valve A yog qhov ntiav, sab nrauv ntawm lub valve B yog qhov chaw, qhov txheej txheem ntawm valve C yog qhov chaw, thiab sab nrauv ntawm valve C yog qhov chaw. Valves A thiab B yog them nrog cov khoom siv corrosion. Lub valve A thiab B tau tawg ntawm qhov khoov, sab nraud ntawm qhov khoov yog raws li lub valve, lub nplhaib valve lub qhov ncauj B yog tawg mus rau qhov kawg, thiab cov xub dawb ntawm qhov tawg ntawm qhov chaw ntawm lub valve A yog cim. Los ntawm cov saum toj no, cov kab nrib pleb yog nyob txhua qhov chaw, cov kab nrib pleb yog qhov loj tshaj, thiab cov kab nrib pleb yog nyob txhua qhov chaw.

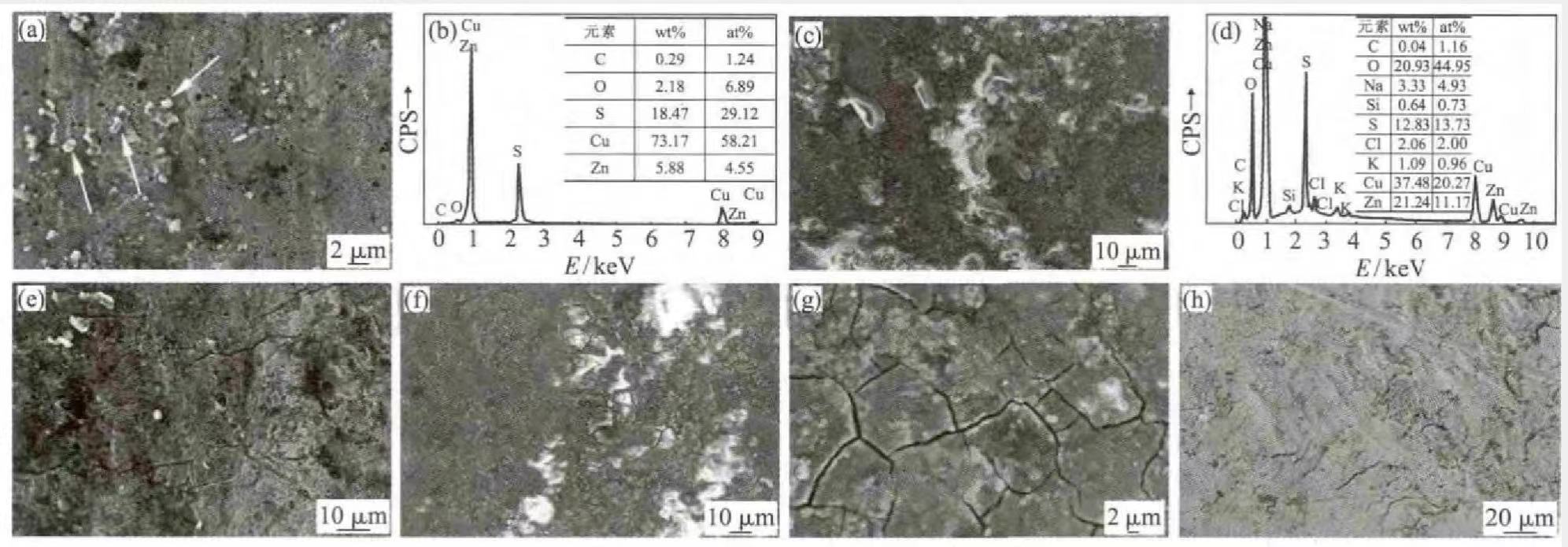

Ib seem ntawm covlog tsheb valveCov qauv A, B, thiab C raug txiav los ntawm qhov khoov, thiab qhov chaw morphology tau soj ntsuam nrog ZEISS-SUPRA55 scanning electron microscope, thiab cov cheeb tsam micro cheeb tsam tau txheeb xyuas nrog EDS. Daim duab 2 (a) qhia txog microstructure ntawm lub valve B nto. Nws tuaj yeem pom tau tias muaj ntau cov xim dawb thiab ci ntsa iab ntawm qhov chaw (qhia los ntawm cov xub dawb hauv daim duab), thiab EDS tsom xam ntawm cov khoom dawb muaj cov ntsiab lus siab ntawm S. Lub zog spectrum tsom xam cov txiaj ntsig ntawm cov khoom dawb yog pom hauv daim duab 2(b).

Daim duab 2 (c) thiab (e) yog qhov chaw microstructures ntawm valve B. Nws tuaj yeem pom los ntawm daim duab 2 (c) tias qhov saum npoo yuav luag tag nrho los ntawm cov khoom siv corrosion, thiab cov ntsiab lus corrosive ntawm cov khoom siv corrosion los ntawm lub zog spectrum tsom xam feem ntau suav nrog S, Cl thiab O, cov ntsiab lus ntawm S nyob rau hauv ib tug neeg txoj hauj lwm yog siab dua, thiab lub zog spectrum tsom xam tau tshwm sim. Nws tuaj yeem pom los ntawm daim duab 2(e) tias muaj cov micro-cracks raws lub nplhaib valve ntawm qhov chaw ntawm lub valve A. Daim duab 2(f) thiab (g) yog cov micro-morphologies ntawm lub valve C, qhov saum npoo kuj yog tag nrho cov khoom siv corrosion, thiab cov khoom corrosive kuj suav nrog S, Cl thiab O, zoo ib yam li daim duab 2(e). Qhov laj thawj rau kev tawg tuaj yeem yog kev ntxhov siab corrosion cracking (SCC) los ntawm cov khoom siv tshuaj tiv thaiv corrosion ntawm lub valve nto. Fig. 2(h) kuj yog qhov chaw microstructure ntawm lub valve C. Nws tuaj yeem pom tau tias qhov saum npoo yog huv si, thiab cov tshuaj lom neeg muaj pes tsawg leeg ntawm qhov tshuaj ntsuam xyuas los ntawm EDS zoo ib yam li cov tooj liab alloy, qhia tias lub valve tsis corroded. Los ntawm kev sib piv cov microscopic morphology thiab tshuaj muaj pes tsawg leeg ntawm peb qhov chaw valve, nws tau pom tias muaj cov xov xwm corrosive xws li S, O thiab Cl nyob rau hauv ib puag ncig ib puag ncig.

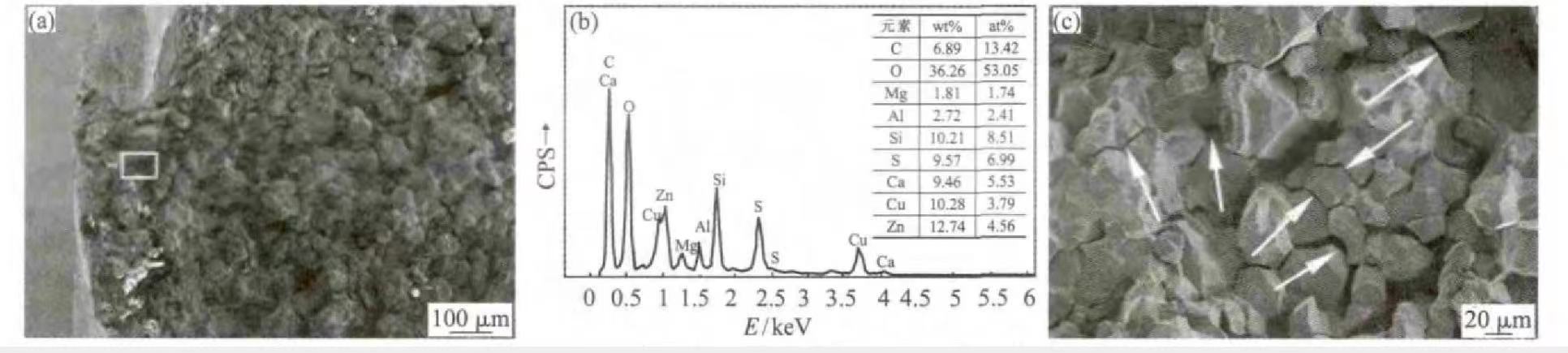

Qhov tawg ntawm lub valve B tau qhib los ntawm kev sim khoov, thiab pom tias qhov tawg tsis nkag mus rau tag nrho cov ntu ntu ntawm lub valve, tawg ntawm sab nraub qaum, thiab tsis tawg ntawm sab rov qab mus rau sab nraub qaum ntawm lub valve. Kev kuaj pom ntawm pob txha pom tau tias cov xim ntawm cov pob txha yog tsaus, qhia tias cov pob txha tawg tau raug corroded, thiab qee qhov ntawm cov pob txha tawg yog xim tsaus, uas qhia tau hais tias qhov corrosion yog qhov hnyav dua hauv cov khoom no. Qhov tawg ntawm lub valve B tau pom nyob rau hauv lub tshuab ntsuas hluav taws xob, raws li pom hauv daim duab 3. Daim duab 3 (a) qhia txog qhov pom ntawm lub pob valve B tawg. Nws tuaj yeem pom tau tias cov pob txha sab nrauv nyob ze ntawm lub valve tau raug them los ntawm cov khoom siv corrosion, dua qhia tias muaj cov xov xwm corrosive hauv ib puag ncig. Raws li lub zog spectrum tsom xam, cov tshuaj lom neeg ntawm cov khoom siv corrosion feem ntau yog S, Cl thiab O, thiab cov ntsiab lus ntawm S thiab O yog qhov siab, raws li qhia hauv daim duab 3(b). Kev soj ntsuam qhov tawg ntawm qhov chaw, nws pom tau tias qhov tawg ntawm kev loj hlob qauv yog raws li hom siv lead ua. Cov kab nrib pleb loj tuaj yeem pom tau los ntawm kev soj ntsuam qhov tawg ntawm qhov loj dua, raws li pom hauv daim duab 3(c). Cov kab nrib pleb thib ob yog cim nrog cov xub dawb hauv daim duab. Corrosion khoom thiab tawg qauv kev loj hlob ntawm cov pob txha tawg dua qhia cov yam ntxwv ntawm kev ntxhov siab corrosion cracking.

Qhov tawg ntawm lub valve A tsis tau qhib, tshem tawm ib ntu ntawm lub valve (xws li txoj haujlwm tawg), zom thiab txhuam cov axial ntawm lub valve, thiab siv Fe Cl3 (5 g) + HCl (50 mL) + C2H5OH (100 mL) tov, thiab cov qauv metallographic thiab tawg kev loj hlob ntawm cov morphology A Observer. Daim duab 4 (a) qhia cov qauv metallographic ntawm lub valve, uas yog α + β dual-theem qauv, thiab β kuj zoo thiab granular thiab faib rau ntawm α-theem matrix. Cov qauv kev nthuav dav ntawm cov kab nrib pleb uas muaj nyob hauv daim duab 4(a), (b). Txij li thaum cov kab nrib pleb tau ntim nrog cov khoom siv corrosion, qhov sib txawv ntawm ob qhov chaw tawg yog qhov dav, thiab nws nyuaj rau kev paub qhov txawv ntawm cov kab nrib pleb. phenomenon ntawm bifurcation. Ntau cov kab nrib pleb (cim nrog cov xub dawb hauv daim duab) kuj tau pom ntawm qhov tawg thawj, saib daim duab 4(c), thiab cov kab nrib pleb no nthuav tawm raws cov nplej. Cov qauv etched valve tau soj ntsuam los ntawm SEM, thiab nws tau pom tias muaj ntau qhov micro-cracks nyob rau hauv lwm txoj hauj lwm thaum uas tig mus rau lub ntsiab tawg. Cov micro-cracks no tshwm sim los ntawm qhov chaw thiab nthuav mus rau sab hauv ntawm lub valve. Cov kab nrib pleb muaj bifurcation thiab txuas ntxiv raws cov nplej, saib daim duab 4 (c), (d). Ib puag ncig thiab kev ntxhov siab lub xeev ntawm cov microcracks no yuav luag zoo ib yam li cov ntawm lub ntsiab tawg, yog li nws tuaj yeem ua pov thawj tias lub ntsiab tawg ntawm daim ntawv nthuav tawm kuj yog intergranular, uas kuj tau lees paub los ntawm kev soj ntsuam pob txha ntawm valve B. Lub bifurcation tshwm sim ntawm qhov tawg dua qhia cov yam ntxwv ntawm kev ntxhov siab corrosion tawg ntawm lub valve.

2. Kev tshuaj xyuas thiab kev sib tham

Yuav kom suav tau, nws tuaj yeem suav tau tias qhov kev puas tsuaj ntawm lub valve yog tshwm sim los ntawm kev ntxhov siab corrosion tawg los ntawm SO2. Kev ntxhov siab corrosion cracking feem ntau yuav tsum tau ua kom tau raws li peb yam xwm txheej: (1) cov ntaub ntawv rhiab rau kev ntxhov siab corrosion; (2) corrosive nruab nrab rhiab heev rau tooj liab alloys; (3) tej yam kev nyuaj siab.

Nws yog feem ntau ntseeg tias cov hlau ntshiab tsis raug kev nyuaj siab corrosion, thiab tag nrho cov alloys raug kev nyuaj siab corrosion mus rau qhov sib txawv. Rau cov khoom siv tooj dag, feem ntau ntseeg tau tias cov qauv dual-theem muaj kev ntxhov siab ntau dua corrosion dua li cov qauv ib-theem. Nws tau raug tshaj tawm nyob rau hauv cov ntaub ntawv hais tias thaum Zn cov ntsiab lus nyob rau hauv cov khoom siv tooj dag siab tshaj 20%, nws muaj kev ntxhov siab ntau dua corrosion, thiab siab dua cov ntsiab lus Zn, qhov siab dua qhov kev ntxhov siab corrosion. Lub metallographic qauv ntawm cov roj nozzle nyob rau hauv cov ntaub ntawv no yog ib tug α + β dual-theem alloy, thiab cov ntsiab lus Zn yog hais txog 35%, deb tshaj 20%, yog li nws muaj ib tug siab corrosion rhiab heev rhiab heev thiab ua tau raws li cov ntaub ntawv uas yuav tsum tau rau kev nyuaj siab corrosion cracking.

Rau cov khoom siv tooj dag, yog tias tsis muaj kev ntxhov siab annealing tsis ua tom qab ua haujlwm txias deformation, kev ntxhov siab corrosion yuav tshwm sim nyob rau hauv qhov tsim nyog kev ntxhov siab thiab corrosive ib puag ncig. Cov kev ntxhov siab uas ua rau muaj kev ntxhov siab corrosion tawg yog feem ntau hauv zos tensile kev nyuaj siab, uas tuaj yeem siv kev ntxhov siab lossis kev ntxhov siab. Tom qab lub tsheb log yog inflated, tensile kev nyuaj siab yuav raug generated raws li axial kev taw qhia ntawm lub cua nozzle vim lub siab siab nyob rau hauv lub log tsheb, uas yuav ua rau ib ncig ntawm cov kab nrib pleb nyob rau hauv cov huab cua nozzle. Lub tensile kev nyuaj siab tshwm sim los ntawm lub sab hauv lub siab ntawm lub log yuav yooj yim xam raws li σ = p R / 2t (qhov twg p yog lub sab hauv siab ntawm lub log, R yog lub puab txoj kab uas hla ntawm lub valve, thiab t yog lub phab ntsa thickness ntawm lub valve). Txawm li cas los xij, feem ntau, qhov kev ntxhov siab tensile tsim los ntawm lub siab sab hauv ntawm lub log tsheb tsis loj heev, thiab cov txiaj ntsig ntawm cov kev ntxhov siab seem yuav tsum tau xav txog. Cov hauj lwm tawg ntawm cov roj nozzles yog tag nrho ntawm lub nraub qaum, thiab nws yog qhov pom tseeb tias qhov seem deformation ntawm lub nraub qaum yog loj, thiab muaj qhov seem tensile stress nyob ntawd. Qhov tseeb, nyob rau hauv ntau cov khoom siv tooj liab alloy, kev ntxhov siab corrosion cracking yog tsis tshua muaj tshwm sim los ntawm kev tsim kev ntxhov siab, thiab feem ntau ntawm lawv yog tshwm sim los ntawm residual stresses uas tsis pom thiab tsis quav ntsej. Nyob rau hauv cov ntaub ntawv no, nyob rau hauv lub rov qab khoov ntawm lub valve, cov kev taw qhia ntawm tensile kev nyuaj siab generated los ntawm lub internal siab ntawm lub log yog raws li cov kev taw qhia ntawm cov residual kev nyuaj siab, thiab lub superposition ntawm ob qhov kev ntxhov siab muab cov kev ntxhov siab rau SCC.

3. Cov lus xaus thiab cov lus qhia

Xaus:

Lub cracking ntawmlog tsheb valveFeem ntau yog tshwm sim los ntawm kev ntxhov siab corrosion tawg los ntawm SO2.

Tswv yim

(1) Txheeb xyuas qhov chaw ntawm corrosive nruab nrab hauv ib puag ncig ib puag nciglog tsheb valve, thiab sim kom tsis txhob muaj kev sib cuag ncaj qha nrog qhov nruab nrab corrosive ib puag ncig. Piv txwv li, ib txheej ntawm cov tshuaj tiv thaiv corrosion tuaj yeem siv rau saum npoo ntawm lub valve.

(2) Qhov seem tensile kev ntxhov siab ntawm kev ua haujlwm txias tuaj yeem raug tshem tawm los ntawm cov txheej txheem tsim nyog, xws li kev ntxhov siab nyem annealing tom qab khoov.

Post lub sij hawm: Sep-23-2022