1. Cov yam ntxwv ntawm cov khoom ua haujlwm

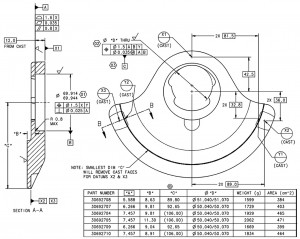

Cov duab ntawm lub workpiece nyias-walledlog lujyog cov kiv cua zoo, cov khoom siv yog QT600, hardness yog 187-255 HBW, sab hauv yog qhov tshwj xeeb zoo li lub qhov, thiab qhov thinnest yog 4 hli tuab. Qhov yuav tsum tau muaj qhov tseeb ntawm qhov ntsuas qhov sib npaug yog pom nyob rau hauv daim duab 1. Txoj kab uas hla ntawm qhov chaw nruab nrab B benchmark yog Φ69.914-69.944 hli, thiab qhov kam rau ua tsuas yog 0.03 hli. Hauv qab no yog ib qhov profiled dawb paug. Kev txiav txiav yog ua tiav thaum machining C siv lub qhov thiab lub voj voog sab nraud. Phab ntsa tuab ntawm no tsuas yog 4 hli, uas yog ib qho yooj yim los tsim kev txiav kev ntxhov siab thiab deformation thiab cuam tshuam rau qhov siab ntev ntawm B siv qhov, uas yog ib qho nyuaj rau kev ua haujlwm.

2. Hidden Dangers Of Traditional Craft

Nyias-walled qhov chaw yog yooj yim deformed thaum lub sij hawm milling txheej txheem, feem ntau yog vim lub deformation tshwm sim los ntawm tej kev nyuaj siab thiab clamping. Cov txheej txheem ua haujlwm ib txwm ua tiav los ntawm CNC machining chaw thiab CNC tshuab dhos, uas tau muab faib ua ob txheej txheem. Ib qho yog OP10 txheej txheem. Siv lub Φ60 hli disc milling cutter kom ntxhib thiab ua tiav lub dav hlau sab saud mus rau qhov loj ntawm daim duab, siv Φ20 mm alloy milling cutter rau ntxhib zeb lub puab lub qhov Φ51.04-51.07 mm rau Φ50.7 mm (tawm 0.3-0.4 mm), siv ib tug Φ20 puab hoom txiav. Φ69.914 ~ 69.944 mm rau Φ69.6 mm (tawm 0.3 ~ 0.4 mm), nplua boring puab lub qhov Φ51.04 ~ 51.07 mm thiab Φ69.914 ~ 69.944 mm nrog nplua boring cutter nrog ob. Qhov thib ob yog txheej txheem OP20. Lub voj voog sab nrauv "C" ntawm qhov ntxhib thiab zoo tig yog rau cov kev cai ntawm kev kos duab.

Lub machining nyuaj ntawm lublog luj, qhov siv lub qhov B, tau machined rau qhov loj yuav tsum tau los ntawm daim duab nyob rau hauv tus txheej txheem OP10. Tshem tawm lub workpiece thiab ntsuas txoj kab uas hla ntawm qhov siv qhov B, Φ69.914 ~ 69.944 mm, thiab ovality yuam kev yog 0.005 ~ 0.015 hli, thiab qhov luaj li cas raws li qhov yuav tsum tau ntawm daim duab. Txawm li cas los xij, tom qab OP20 ua tiav, tshem tawm cov khoom ua haujlwm thiab ntsuas txoj kab uas hla ntawm lub qhov siv B, Φ69.914-69.944 mm, thiab ovality yuam kev yog 0.03-0.04 hli. Nws tuaj yeem pom tias txoj kab uas hla tau dhau qhov kev xav tau ntawm daim duab kos.

3. Kev daws teeb meem

Txhim kho cov cuab yeej. Txawm hais tias tus tsim ntawm cov cuab yeej clamping yog qhov tseeb muaj qhov cuam tshuam ncaj qha rau kev ua kom qhov tseeb ntawm lub tshuab ua haujlwm, txhim kho kev ua haujlwm ntawm kev ua haujlwm thiab txo cov kev siv zog ntawm cov neeg ua haujlwm. Vim yog cov yam ntxwv ntawm nyias-walled qhov chaw, lub zog clamping ntau dhau los yog lub zog tsis sib xws yuav ua rau elastic deformation ntawm lub workpiece, uas yuav cuam tshuam qhov tseeb ntawm qhov loj thiab cov duab siab ntev ntawm qhov, thiab nws thiaj li ua rau qhov loj ntawm qhov ua tiav ntawm qhov kev zam. Txhawm rau daws qhov teeb meem no, tus qauv thiab qhov loj ntawm lub tog raj kheej clamping thiab lub tog raj kheej txhawb nqa yuav tsum tau ua tib zoo xaiv thaum tsim cov cuab yeej hydraulic.

Post lub sij hawm: Aug-19-2022