1. Cov ntsiab lus

Lub raj sab hauv yog cov khoom siv roj hmab nyias nyias, thiab qee cov khoom pov tseg yog inevitably tsim thaum lub sij hawm tsim khoom, uas tsis tuaj yeem txuam nrog cov log tsheb sab nrauv, tab sis nwsli qubtsis zoo, thiab cov li qub no tuaj yeem rov ua dua thiab rov siv dua rau kev tsim cov raj sab hauv. Peb lub tuam txhab tau ua qee qhov kev sim ntawm kev rov ua dua tshiab thiab rov siv dua ntawm cov raj sab hauv, tab sis qhov zoo ntawm cov khoom siv rov ua dua qub yog qhov tsis zoo, thiab lub zog sib txuas ntawm lub hauv paus valve thiab cov roj hmab ncoo yog tsawg, thiab nws yuav tsum tau rov qab siv dua ua ntej nws tuaj yeem siv tau. .

Qhov kev ua haujlwm no txhim kho cov txheej txheem rov ua dua tshiab ntawm cov khoom pov tseg thiab cov khoom siv hauv lub raj tsis zoo txhawm rau txo cov khib nyiab thiab txhim kho cov txiaj ntsig kev lag luam ntawm kev lag luam.

2. Kev tshuaj xyuas qhov teeb meem

Cov txheej txheem rov ua dua ntawm qhov qub pov tseg thiab tsis zooinner tube li qubyog raws li nram no: pov tseg thiab puas inner tube li qub → incineration → acid kho → single-mode vulcanization (adhesive pads) → bristles ntawm cov roj hmab pads.

Cov teeb meem ntawm cov txheej txheem saum toj no yog raws li hauv qab no.

(1) Incineration ntawm pov tseg thiab puas inner tube li qub yuav ua rau ib puag ncig muaj kuab paug. Lub cev lub cev rov qab siv tau yooj yim deformed thiab muaj qhov qias neeg. Nws yog ib qho nyuaj los ntxuav nws thaum lub sij hawm kho acid, thiab nws yog ib qho yooj yim uas yuav ua rau muaj kuab paug rau lwm yam txheej txheem.

(2) Txhawm rau kom yooj yim rau kev tshem tawm thiab tshem tawm lub valve, tus qauv tsim ntawm vulcanization pwm yog ib qho pwm thiab muab faib ua 3 ntu. Ib hom vulcanization yuav siv sij hawm ntev, kev ua haujlwm tsawg, kev siv zog siab thiab kev siv hluav taws xob, thiab sab nrauv ntawm lub vulcanized valve yog feem ntau ua rau cov roj hmab tsis zoo, cov roj hmab qhwv lub qhov ncauj ntawm lub qhov ncauj, thiab qhov zoo ntawm lub valve tsis ua raws li qhov yuav tsum tau ua. Lub zog nplaum ntawm cov nplaum nplaum kuj tsis ruaj khov.

(3) Cov phau ntawv bristling ntawm cov roj hmab ncoo muaj cov teeb meem ntawm kev siv zog ua haujlwm siab, kev ua haujlwm qis, thiab qhov tsis sib xws, uas cuam tshuam rau kev sib txuas ntawm cov roj hmab ncoo thiab cov khoom siv roj hmab ntawm lub raj sab hauv.

3 Txhim kho cov nyhuv

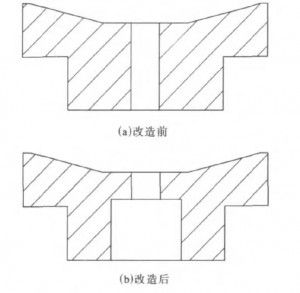

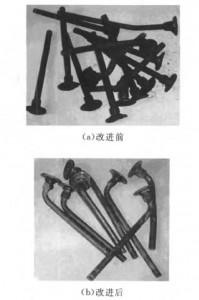

Daim duab 2 qhia tau hais tias lub nozzle lub cev rov qab ua ntej thiab tom qab kev txhim kho ntawm cov txheej txheem ua raws. Nws tuaj yeem pom los ntawm daim duab 2 tias lub cev nozzle tau kho los ntawm cov txheej txheem txhim kho yog pom tseeb huv si, thiab lub cev nozzle yuav luag tsis zoo. Nrog rau cov txheej txheem txhim kho, cov kua qaub thiab dej siv tsawg dua, thiab ib puag ncig muaj kuab paug tsawg dua, thiab cov ntaub qhwv cov roj hmab txiav tuaj yeem rov ua dua los tsim cov roj hmab rov qab.

Ua ntej kev txhim kho, cov nyhuv hloov pauv ntawm cov pwm tsis zoo, thiab cov vulcanization yuav siv sij hawm 15 feeb. Raws li kev ua haujlwm ntawm cov vulcanizer uas twb muaj lawm, tsuas yog 4 li qub tuaj yeem ua vulcanized ib zaug, thiab txog 16 li qub tuaj yeem tsim tau ib teev, uas tsis suav nrog kev thauj khoom pwm. sij hawm. Nrog rau kev hloov pauv ua ke pwm, nws tsuas yog siv sijhawm 5 feeb rau vulcanize, 25 li qub tuaj yeem ua vulcanized txhua lub sijhawm, thiab txog 300 li qub tuaj yeem tsim tau ib teev. Nws yog ib qho yooj yim rau nruab thiab demould, thiab kev siv zog tsawg.

Nrog rau kev hloov pwm thiab lub tshuab deburring, ob qho tib si ncaj li qub thiab nkhaus li qub tuaj yeem tsim tau, thiab cov txheej txheem txheej txheem yog tib yam. Tsis muaj qhov sib txawv ntawm qhov pom thiab qhov zoo ntawm cov li qub uas tau siv thiab rov siv dua los ntawm cov txheej txheem txhim kho thiab cov li qub tshiab. Cov txiaj ntsig kev sim qhia tau hais tias qhov nruab nrab lub zog sib txuas ntawm lub hauv paus valve thiab cov roj hmab ncoo rov ua dua los ntawm cov txheej txheem txhim kho yog 12.8 kN m-1, thaum lub zog nruab nrab ntawm kev sib txuas ntawm lub hauv paus tshiab thiab cov roj hmab ncoo yog 12.9 kN m-1, Cov qauv kev lag luam xav kom lub zog sib txuas tsis pub tsawg dua 7 kN·m-1.

Tom qab ntau tshaj kaum xyoo ntawm kev loj hlob sai, Tuam Tshoj txoj kev lag luam valve tau dominated lub ntiaj teb no. Tam sim no, kuv lub teb chaws lub valve ntau lawm tso nyiaj rau ntau tshaj 70% ntawm lub ntiaj teb no tag nrho cov khoom ntawm li qub, qeb duas nyob rau hauv lub ntiaj teb no ntau lawm thiab muag khoom li qub. Yuav kom ua tau raws li cov kev xav tau ntawm kev lag luam hauv tsev thiab thoob ntiaj teb, tubeless tus nqi ntawm cov li qub tau maj mam nce. Nyob rau hauv 2015, cov zis ntawm tubeless li qub tau suav rau ntau tshaj li ib nrab ntawm tag nrho cov zis ntawm li qub. Lub lag luam loj loj hauv kev lag luam xav tau tas li txhawb txoj kev loj hlob ntawm kev lag luam.

Kev lag luam valve xav tau yog muab faib ua OEM kev lag luam thiab AM lag luam. Cov ntaub ntawv tshiab tshaj plaws qhia tau hais tias huab cua valve yog qhov tseem ceeb ntawm kev nyab xeeb ntawm lub tsheb log module. Vim tias nws tau raug sab nraud rau lub sijhawm ntev, nws yuav tsum tau tiv taus ntau yam hnyav ib puag ncig erosions. Valves feem ntau hloov thaum lub sij hawm soj ntsuam txhua xyoo thiab hloov lub log tsheb, yog li qhov kev thov rau li qub hauv AM kev lag luam yog ntau dua li hauv khw OEM.

4. Epilogue

Nrog kev txhim kho thev naus laus zis, tsuav yog lub cev valve tsis deformed, nws tuaj yeem rov ua dua. Qhov zoo ntawm recycled cua li qub raws li cov kev xav tau ntawm kev siv, uas tuaj yeem txo qhov kev siv ntawm cov khoom siv raw thiab lub zog, txo cov nqi tsim khoom ntawm cov raj sab hauv, thiab txhim kho cov txiaj ntsig ntawm kev lag luam.

Post lub sij hawm: Dec-02-2022